Having the correct wheelbase on the chassis and placing the bodies and loads in the proper place will assure that the axles are located correctly.

Performing a weight distribution analysis can prevent building trucks that are overloaded in normal use, causing problems for users and the equipment installer. Overloads can shorten the live of a vehicle and its components. Overloads can also prevent compliance with weight laws and federal safety standards.

What & Why of Truck Weight Distribution

Weight distribution is the amount of the total vehicle weight imposed on the ground at an axle, group of axles, or an individual wheel. The weight on a truck must be distributed on the axles to comply with the chassis manufacturer's axle ratings and

weight

laws.

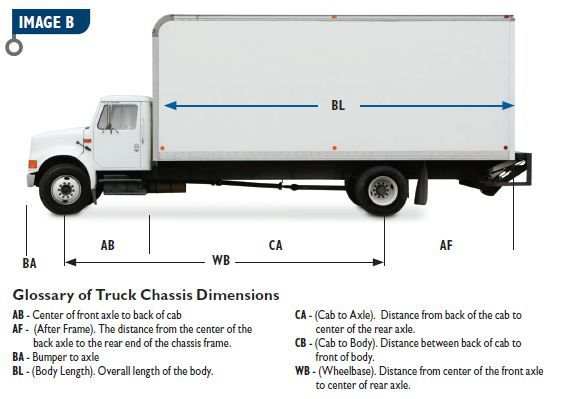

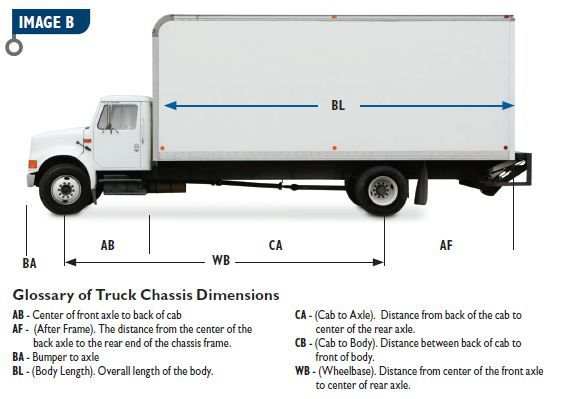

A glossary of truck chassis dimensions.

Having the correct wheelbase on the

chassis

and placing bodies and loads in the proper place will ensure that axles are loaded correctly. Performing a weight distribution analysis identifies the proper axle loadings before building a truck.

Axle capacities

are limited either by the axle capacity or legal weight limits, whichever is lower. Both trucks in Image A have a front axle rated at 12,000 lbs., limiting the weight on those axles. The rear axle on the single-drive truck is limited by the axle capacity or legal weight restrictions to 20,000 lbs. The two rear axles on the tandem-drive truck are limited either by axle capacities or legal weight restrictions to 17,000 lbs. for each axle, or a total of 34,000 lbs. for the pair of axles.

Impact of a Truck's Center of Gravity

The center of gravity of an object does not have to be in the material of the object (Image C). When considering a solid ball, such as a billiard ball, it is obvious the center of gravity is the center of the ball and in the material that makes up the object. In the case of a hollow ball, the center of gravity is also at the center, but it is not in the material. If the center of gravity of a truck body is in the material of the body, it is coincidence. Most of the time, the center of gravity of a truck body is in the air, similar to the hollow ball example.

The centers-of-gravity of the truck chassis is shown at the top of the frame rail at the cab and body and cargo centers-of-gravity are shown with a single symbol at the center of the body about a third of the body height above the floor.

Each truck component, including passengers and cargo, have a center of gravity. For example, the center of gravity of the truck chassis is shown at the top of the frame rail at the back of the cab and the body and cargo centers of gravity are shown with a single symbol at the center of the body about a third of the body height above the floor.For the process of calculating weight distribution on the axles, the horizontal centers of gravity are used. If individual wheel loadings are calculated, the lateral centers of gravity are also used. Unless a lateral center of gravity is given for the chassis or a component, it is assumed to be on the centerline of the chassis.

The horizontal and vertical centers of gravity for the entire sample truck is shown with the center of gravity (CG) symbol.

Lateral centers of gravity (CGs) are measured from the vehicle centerline toward the right or passenger side as positive, left as negative. These are used to calculate individual wheel loadings and incompliance calculations.

"Moments" are a force or weight times a distance. One pound of force times one foot is 1 ft.-lb. One pound of force times 12 inches is 12 in.-lbs. They are both the same moment. Moments can be used to calculate CGs, weight distribution, frame loads, hoist capacities, and effective wheelbase.Moments provide a way to combine a number of components or items to calculate a CG for them as a group (Image F). When the CG distance is known for all items combined, it is possible to calculate the weight on each axle. Moments in one direction must match the moments in the other. The down moment of the chassis plus the down moment of the body must equal the up moment on the rear axle.

Lateral CGs measured from the vehicle centerline with toward the right or passenger side as positive. Toward the left is negative. They are used to calculate individual wheel loadings and inccompliance calculations.

The Weight Distribution Analysis Process

Calculate the weight distribution of a vehicle using the following steps:

Determine the weight and center of gravity location for all of the components and items to be considered

Multiply the center of gravity distance times the weight to get the moment for each component and item.

Add all of the moments and divide by the wheelbase to get the weight on the rear axle.

Subtract the rear axle weight from the total weight to get the front axle weight.

When you know the CGdistance for all of the items combined, you can calculate the weight on each axle.

Glossary of Terms

AB

- Center of front axle to back of cab

AF

-(After Frame). The distance from the center of the back axle to the rear end of the chassis frame.

BA

- Bumper to axle

BL

- (Body Length). Overall length of the body.

CA

- (Cab to Axle).Distance from back of the cab to center of the rear axle.

CB

- (Cab to Body). Distance between back of cab to front of body.

WB

- (Wheelbase). Distance from center of the front axle to center of rear axle.

RELATED:

How to Avoid Over- and Under-Spec'ing Pitfalls